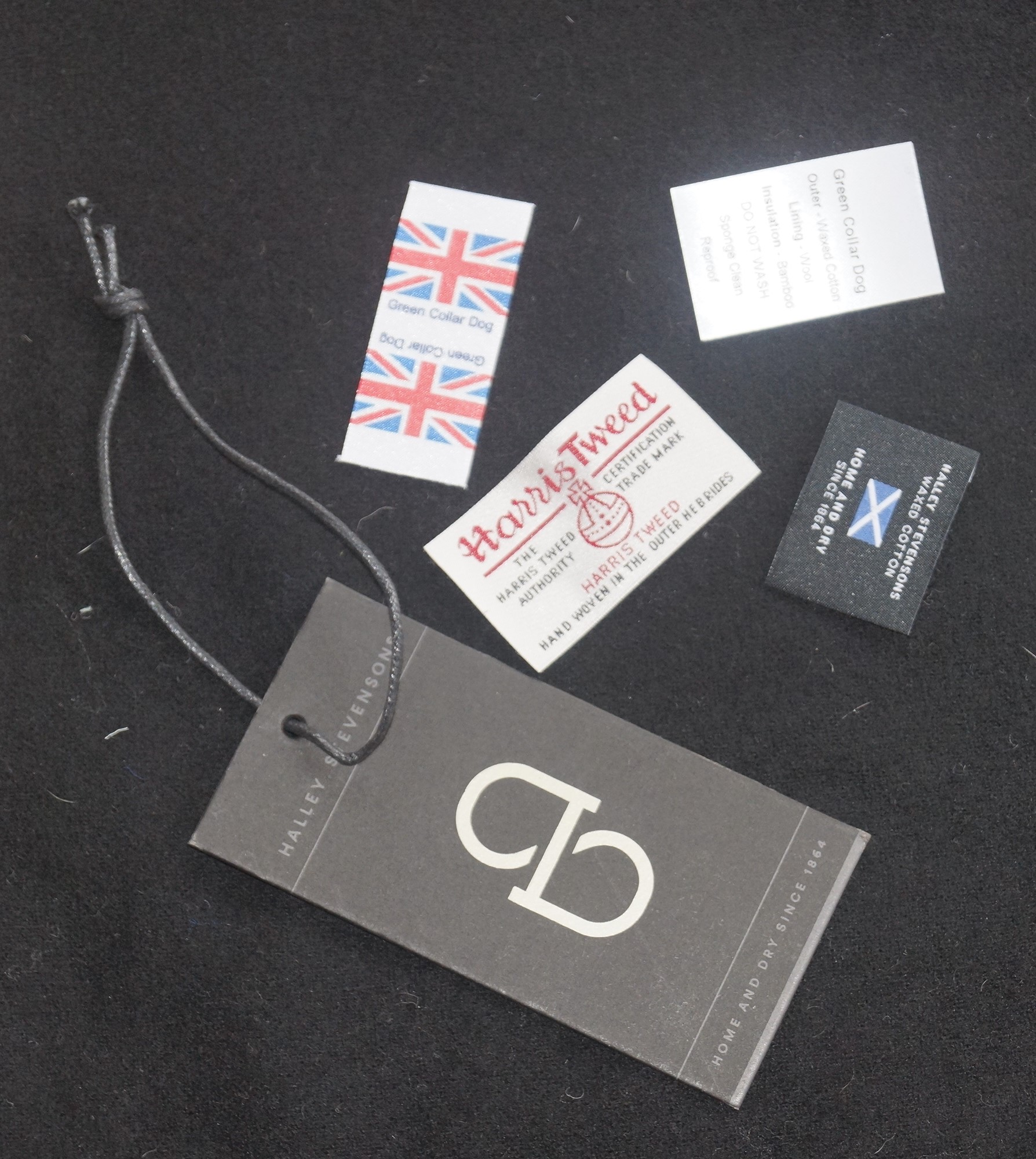

A selection of the haberdashery items used in the manufacturing.

The pattern is placed on the fabric before cutting out.

The three layers of the coat are brought together and tacked into place. On the waterproof and showerproof coats the tacking is inside the line of the stitching to ensure that there are no holes made in the outer fabric. This ensures that the integrity of the fabric is not compromised – even by a needle hole.

Once backstitched the fabric is trimmed, ready for the application of the bias binding.

Once the three layers have been trimmed, the bias binding can be sewn on. The stitches go through not only the binding but also through all three layers of the coat fabric. This provides a further line of stitching to ensure the coat seams are solid.

Once the bias binding has been stitched on both sides of the coat, and the fastenings sewn into place (hook and loop or snap fastenings) the labels are sewn into place.

The coat is now ready to give lifelong wear and comfort to its new owner.

For dog wear that is second only to the coat the dog was born with.